Safely Control and Eliminate Pervasive

Fungi/Mold/Algae Growth and Contamination

Prevention Is The Best protection

Grow With Complete Confidence

Shiield’s Eco-Friendly Environmental Solutions continue to provide a completely safe, amazingly effective, and budget friendly efficient solution to pervasive and costly problems with Cannabis cultivation:

- Alternaria

- Aspergillus

- Botrytis

- Fusarium

- Penicillium

- Trichoderma

- And many, many others

A Proven Successful Process

Establish The Baseline

Lab

Testing

Devise

A Plan

The Shiield ™ Application

Scheduled

Re-Applications

Prevention

= Winning

What Is Shiield ™?

Shiield ™ is a proven process utilizing an antimicrobial, bacteriostatic, fungistatic barrier with extended protection against fungi.

Effective Against Pathogenic Fungi And Molds:

- Aspergillus

- Alternaria

- Cladosporium

- Penicillium

- Trichoderma

- Stachybotrys

- Approved by the FDA for use on all food contact surfaces and all industries.

- Prevents mold and mildew growth on surfaces (filters, grow trays, ductwork, triming stations, etc.).

- Environmentally friendly, non-leaching, non-toxic, hypoallergenic antimicrobial technology.

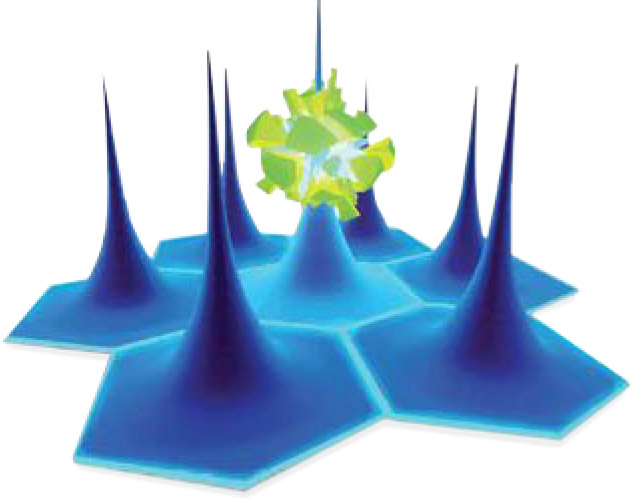

Active antimicrobial molecule “spike ” impales microbes, destroying it on contact, while providing lasting, durable efficacy.

Case Study

The Challenge: Eliminate pervasive Aspergillus growth and contamination within industry and regulatory guidelines and requirements.

The Facilities Issue: Significant registered airborne and surface levels (in excess of 4,000 m/3) of Aspergillus found in grow, dry, trim, and packaging areas. Extremely high ATP registered RLU readings (in excess of 12,000 RLU’s) even after spatial sanitized cleaning. Frequent crop testing failures and negative financial impact.

The Treatment: We applied Shiield’s antimicrobial barrier via an electro-static application to all grow room surfaces including walls, ceilings, floors, doors, lighting, shelving, piping, and fixtures after room was cleared from previous crop, wiped down and completely dry.

We reapplied after each grow cycle (approximately 60 days).

We continued to apply Shiield monthly to each dry room after spatial cleaning and dry as well as monthly applications to trim and packaging areas and equipment.

The Results

Air Testing Summary (Mold specific Microorganisms):

Conducted over 40 Air Test Events and submitted with full Chain of Custody tracking to EPA registered laboratory for Full Microorganism Analysis and Enumeration.

Result – No Registered Airborne Aspergillus found in any of the spaces following Shiield applications.

Bio-Tape & Swap Culture Testing Summary (Mold Specific Microorganisms):

Bio Tape samples gathered via a Certified Testing Engineer and submitted with full Chain of Custody tracking to EPA registered laboratory for Full Microorganism Analysis and Enumeration.

Result – No Registered Surface based Aspergillus found in any of the spaces following Shiield applications.

ATP Testing Summary:

ATP Bioluminescence Testing performed in all areas regularly and logged for ongoing tracking. ATP Indicates overall level of cleanliness. ATP testing context; 30RLU is the limit within the Food Prep Industry. Hospitals and Sensitive areas utilize ATP to gauge their levels of cleanliness typically seeking readings of 100-500 RLU. The Average RLU prior to Shiield was well over 1K’s RLU with many reaching into the 10K’s.

Result – After Shiield applications, the average RLU Reading over 80 Test Events in the Cultivation Area: 72 RLU.

We're Experts At Solutions

Shiield is a team of experts in mold and other contamination detection, remediation planning, and preventative solutions. While Prevention is our constant mission, Shiield is your best first step in determining the scope and scale of a potential mold/fungi concern.

Our training and experience give us the advantage where to look and what to expect. In fact, initial discovery and testing is far less costly than you think and no question less costly than a harmful mold or fungal issue going unchecked and continue to colonize.

We will help you save costly labor hours (-25%*), reduce toxic and harmful chemical use (-20%)*, and significantly improve your facilities hygienic performance (+1400%*).

In ALL cases, Shiield’s system of Prevention is always considered a best practice in avoiding remediation’s, breakouts, batch failures while providing a healthier environment for both cultivation and cultivators.

*according to Shiield client studies and feedback

Why Shiield Is Like No Other Solution?

- EPA & FDA Approved for even food contact surfaces (It’s that safe!).

- Broad spectrum of Pathogen inactivation.

- Not a chemical kill – game changing nano-technology destroys and prevents pathogens mechanically.

- Long Term Efficacy & Durability (a minimum of 30 days effectiveness)

- Non-evasive application schedule.

- Surface AND Air Quality effectiveness due to Electro-Static applications and HVAC system treatments.

- Extremely cost-effective including savings recovery from modified protocols and improved hygienic performance.

- Staff peace of mind supporting both their labor efforts AND their health

- We can even treat staff apparel avoiding carrier cross contamination.

- Lastly….what’s good and safe enough for the cultivation space is just as effective and safe enough for all other facility spaces avoiding cross- contamination challenges.

A large part of what we do is education and we’d love to discuss your needs as well as answer any of your questions about our solutions.

We service commercial grow facilities in the greater Northern California area.